Protecting Chiller Tube Sheets & Water Boxes

PREVENT CORROSION & EXTEND SERVICE LIFE

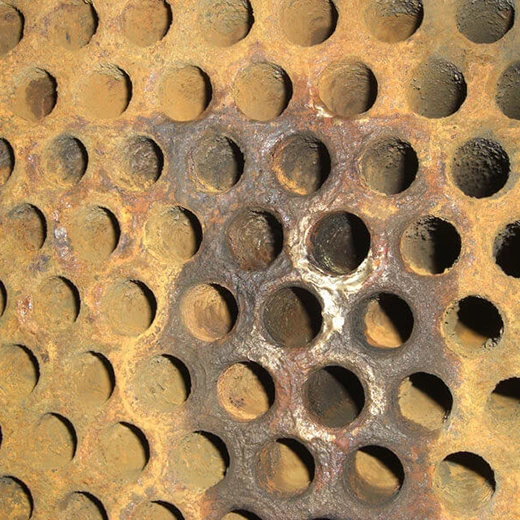

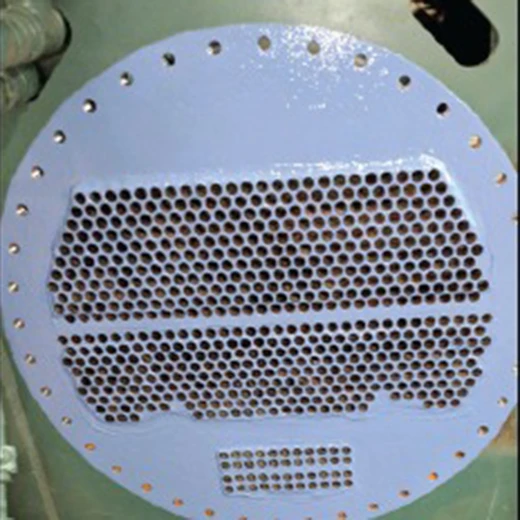

Protecting Chiller Tube Sheets & Water Boxes helps prevent corrosion, extend equipment life, and improve efficiency with coatings, linings, and regular maintenance. WEATHER MAKERS offer a comprehensive restoration and protective coatings solution for heat exchangers .

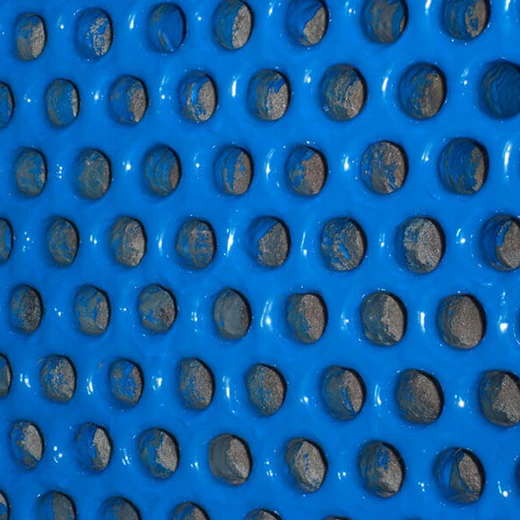

Our experts will assess and remove existing corrosive damage, rebuild surfaces for optimal flow and apply proprietary coatings to protect tube sheets, baffle plates, end bells and water boxes from corrosion. Our superior Ceramic coatings are formulated to bond to corrosion prone surfaces, increase thermal conductivity, prevent galvanic corrosion, withstand long term immersion, and resists a range of chemicals. Quick-cure technology allows for minimal downtime.

CERAMIC Coating provides long term corrosion resistant protection and improve efficiency by creating smooth surfaces for water passage and improves equipment health, adding years to a system’s service life.

Maximize Chiller Performance with Advanced Coating Solutions

Ceramic Coating enhances the durability and efficiency of your equipment. Our coatings improve tube-to-tube sheet joint strength, protect against corrosion and erosion, and increase the service life of your chillers.

Benefits of Ceramic Coating:

- Improves tube-to-tube sheet joint Strength

- Protects against corrosion, erosion and cavitation

- Increases the service life of equipment

- Adds a non-conductive layer to the tube sheet, insulating it from electri¬cal conduction

- Application requires minimal down¬ time and easily pays for itself in savings

- Decreases inlet turbulence