Demonstrated Capability in Chiller Maintenance

Competence & Expertise in Chiller Maintenance

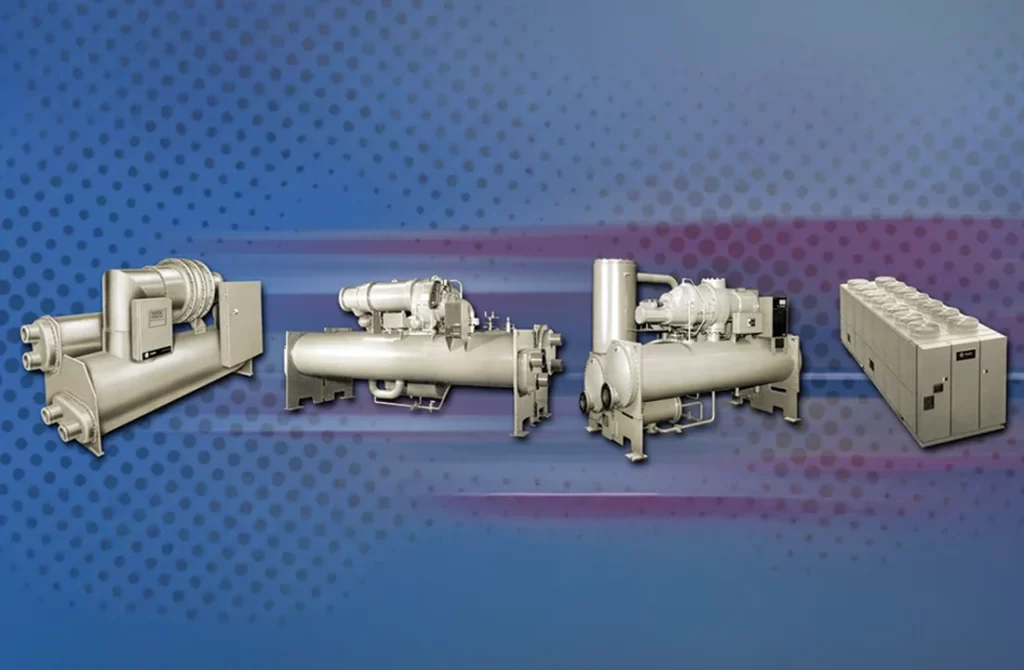

Chiller Maintenance – Expert solutions for efficient chiller performance, repairs, and servicing to ensure optimal cooling and system longevity. Weather Makers specializes in the service, repair, retrofitting, modernization and maintenance of centrifugal, screw, reciprocating and absorption liquid chillers, as well as ancillary equipment. Our expertise and service standards exceed those set by chiller manufacturers, ensuring superior performance and reliability.

We offer a range of value-added services, including energy optimization and Non-Destructive Diagnostics (NDD), carried out by our team of highly skilled service engineers.

Our specialized services include:

- Refrigerant Analysis

- Eddy Current Tube Analysis

- Vibration Analysis

- Thermographic Infrared Testing and Analysis

- Spectrochemical Oil Analysis

- Ultrasonic Water Flow Analysis and Measurement

- Motor Insulation Testing

At Weather Makers, we are committed to delivering advanced maintenance solutions that enhance efficiency, reliability and longevity for chiller systems across Dubai and all over UAE.

Value Added Services

Energy and Environmental Services

At Weather Makers, we take a comprehensive system approach to mechanical services, going beyond routine maintenance to deliver advanced energy and environmental solutions. Our objective is to analyze, develop and implement strategies that enhance overall energy efficiency. By evaluating the entire system—not just the equipment room—we identify opportunities to optimize operations, reduce energy costs and ensure compliance with environmental regulations while integrating effective conservation measures.

Spectrochemical Oil Analysis

- Lubricant Condition: Evaluating the condition of the lubricant determines whether the system fluid remains effective for continued use or requires replacement.

- Contamination: Contaminants such as rust, dirt, water and acid are primary contributors to machine deterioration and failure. Early detection of increased contamination allows for timely corrective actions, preserving oil quality and preventing unnecessary equipment wear.

- Machine Wear: A failing system produces wear particles at an accelerated rate. Identifying and analyzing these particles supports critical maintenance decisions, preventing component failure and unexpected system breakdowns.

Refrigerant Analysis

Weather Makers conducts detailed refrigerant analysis to ensure that refrigerant is free from contamination and fully compliant with standards. This process guarantees the efficiency, reliability and longevity of your chiller system.

Eddy Current Testing

Eddy current analysis is a Non-Destructive electromagnetic testing technique based on the principles of electromagnetic induction. This method is completely safe, involving no hazardous chemicals or radiation. At Weather Makers, we specialize in the inspection of heat exchanger tubing used in commercial air conditioning, power plants, marine, pulp and chemical industries.

Eddy current testing is primarily used for metallic materials, working most effectively on non-magnetic alloys. However, using magnetic saturation techniques, it can also be applied to materials such as Monel, Nickel, Ferralium and other Ferritic Stainless Steels.

Vibration Analysis

Vibration data is collected using specialized handheld data acquisition devices and then digitally transferred for in-depth analysis and reporting.

Vibration analysis provides our service engineers with critical insights into the internal condition of compressor bearings, gears and rotating components. Components such as worn bearings generate unique vibration signals corresponding to their level of damage and rotational speed. Our high-sensitivity vibration monitoring equipment captures these signals, allowing our vibration engineers to assess and diagnose potential failures before they occur.

Thermographic Infrared Analysis

Using heat-sensing scanners and infrared imaging, we detect abnormal temperature patterns in mechanical systems, which often indicate underlying operational issues.

For example, electric motors—which are costly to repair or replace—can experience overheating, a key cause of motor winding failure. Our thermographic analysis identifies these elevated operating temperatures early, helping prevent costly damage.

Additionally, thermographic testing detects problems such as:

- Loose or corroded electrical connections

- Deteriorating wire insulation

- Insufficiently lubricated bearings

Our detailed written report of this testing will include precise recommendations for rectifying any detected issues, allowing for proactive maintenance and breakdown prevention.

Ultrasonic Water Flow Testing

We utilize state-of-the-art ultrasonic flow meters equipped with advanced software capable of:

- Accurately measuring pipe thickness

- Determining exact GPM (Gallons Per Minute) flow rates

- Conducting built-in energy measurement analysis

This innovative technology enables precise water flow monitoring, ensuring optimal system efficiency.

Refrigerant Containment and Management

To comply with global refrigerant regulations, we implement effective recovery, recycling and reclamation processes for refrigerants.

Our expert engineers ensure full compliance with international environmental standards. We keep our clients informed about refrigerant-related legislation, industry trends and optimization opportunities. Based on equipment age and business objectives, we provide customized recommendations to enhance efficiency and sustainability.

Motor Insulation Testing

Motor failures, often caused by winding insulation breakdown, lead to unexpected downtime and costly disruptions. Regular motor insulation testing helps to detect insulation deterioration early, allowing for scheduled, cost-effective repairs.

We utilize meg-ohm testing to assess motor insulation integrity without the need for extensive disassembly. This testing identifies:

- Weak spots in motor windings

- Moisture presence, which accelerates insulation breakdown

- Issues in starters and connecting wire insulation

Following our analysis, we provide a comprehensive report with actionable recommendations, ensuring optimal motor performance and longevity.

Hidden Problems Can Drive Up Operating Costs – Here’s How to Detect and Resolve Them

Your building’s systems may seem to be operating smoothly. Complaints about comfort are minimal, and while energy costs are rising, it appears to be within expected limits. No obvious issues are visible.

But are your systems truly running at maximum efficiency to minimize energy expenses? Could there be hidden inefficiencies that may lead to unexpected failures, costly repairs, and downtime? Is indoor air quality being affected? Have building modifications impacted system performance?

The longer your systems have been in operation, the higher the chances that your energy and maintenance costs are exceeding necessary levels. Fortunately, there is an effective and cost-efficient solution: Predictive Maintenance by Weather Makers.

Welcome to Weather Makers’ Predictive Maintenance

Unexpected equipment failures can lead to operational disruptions, costly repairs and occupant discomfort. With predictive maintenance, potential issues are identified before they escalate—allowing for proactive action at convenient times without disrupting operations in the building.

Using advanced diagnostic tools and testing technologies, we can detect and eliminate hidden system inefficiencies. Our predictive maintenance services help you:

✔ Identify and address minor issues early, preventing them from turning into major, costly repairs

✔ Minimize unplanned downtime, ensuring smooth building operations and occupant comfort

✔ Maintain uninterrupted production, particularly in process-driven applications

✔ Optimize energy consumption, effectively controlling energy expenses

✔ Extend equipment lifespan, delaying the need for expensive replacements

✔ Reduce emergency repair costs, eliminating the need for costly overtime for unscheduled repairs

In short, Weather Makers’ Predictive Maintenance ensures optimal building system performance, empowering you to make informed maintenance decisions while achieving the lowest overall operating costs.

Advanced Hardware and Software for Precision Testing

With extensive experience in the industry, we invest in the best diagnostic tools and technologies to deliver accurate and comprehensive system evaluations. When you choose Weather Makers, you can trust that our assessments provide reliable, actionable insights for optimizing your building’s performance.

Highly Trained Experts for Superior Service

We believe in continuous learning and professional development, ensuring that our technicians receive industry-leading training using the latest educational resources and methodologies. Our experts stay up to date with latest testing technologies and have access to the most advanced diagnostic equipment, guaranteeing top ranking service quality.

With Weather Makers Predictive Maintenance, you gain a smarter, more efficient approach to building system management, helping you reduce costs, improve reliability and enhance overall performance.